Add to Cart

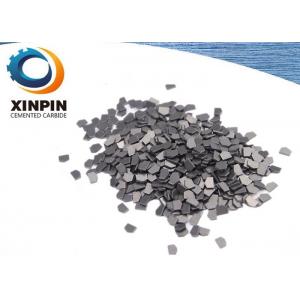

Customized Tungsten Carbide Drill Tips tipped on drill bits for Wood, Ceramic tile

| Grade | ISO CODE | USA CODE | BINDER | DENSITY | HARDNESS | TRANSVERSE RUPTURE STRENGTH | GRAIN SIZE | RECOMMENDEDCUTTING APPLICATIONS |

|---|---|---|---|---|---|---|---|---|

| SM02 | K01 | C4 | 2.8 | 15.0-15.2 | 94.5-94.8 | ≥2400 | ultra-micron | for chipboard, MDF&HDF, laminated board etc |

| SM03 | K01 | C4 | 3 | 15.0-15.2 | 94.0-94.4 | ≥2600 | Sub-micron | for veneer board, MDF & HDF, aluminum extrusion etc |

| SM05 | K01 | C4 | 3.5 | 15.0-15.2 | 93.8-94.0 | ≥3000 | Sub-micron | for hardwood,copper,aluminum, plywood, MDF and Acrylic etc |

| SM06 | K05 | C3 | 4 | 14.9-15.1 | 93.6-93.8 | ≥3200 | Sub-micron | for hardwood,copper,aluminum,plywood,MDF and Acrylic etc |

| SM07A | K05 | C3 | 5 | 14.8-15.0 | 93.2-93.6 | ≥3000 | Sub-micron | for solidwood, hardwood, copper,aluminum,plywood etc |

| XF6 | K10 | C3 | 6 | 14.7-14.9 | 92.0-92.8 | ≥2600 | Fine | for solidwood, hardwood and composite board etc

|

| XF8 | K20 | C2 | 8 | 14.5-14.7 | 91.0-92.0 | ≥2800 | Fine | for construction formwork with nails, non-ferrous metal and various woodworking tools etc |

| XF10 | K30 | C2 | 10 | 14.3-14.5 | 90.5-91.5 | ≥3000 | Fine | for solidwood,hardwood and various woodworking tools etc |

| XK10 | K10 | C2 | 6 | 14.8-15.0 | 90.5-91.0 | ≥2400 | Medium | for solidwood,hardwood

|

| XK20 | K20 | C1 | 8 | 14.6-14.8 | 89.5-90.5 | ≥2600 | Medium | for softwood,solidwood etc

|

Drawing for the tungsten carbide drill bits, which are manufactured at XINPIN work shop and well demanded in india market.

Flow chat for tungsten carbide drill tips

At XINPIN workshop, we always insit:

First,select the top suppliers of raw fresh material, we will not only make te convential chemical analysis for each batch of incoming raw material, but also testing individually the raw material for every order, we set up a strict standard to every grade, which assure the stable performance and reliability of finished products for all customer.

second, advanced automatic pressing machines, vacuum integrated sintering furnace, hot isostatic pressing furnace and professional inspecting equipements to assure the high qualified products during each process.

third, all workers had been trained over 3 months to be qualified operators, and most od our workers have over 2 years experiences of their position.

We at XINPIN assure that your orders will receive individual attention, whether it is big or small, we welcome your testing.